24hr Media Fundamentals Explained

24hr Media Fundamentals Explained

Blog Article

The 9-Minute Rule for 24hr Media

Table of ContentsThe Ultimate Guide To 24hr Media4 Easy Facts About 24hr Media Described24hr Media Things To Know Before You Get ThisRumored Buzz on 24hr MediaThe Buzz on 24hr Media

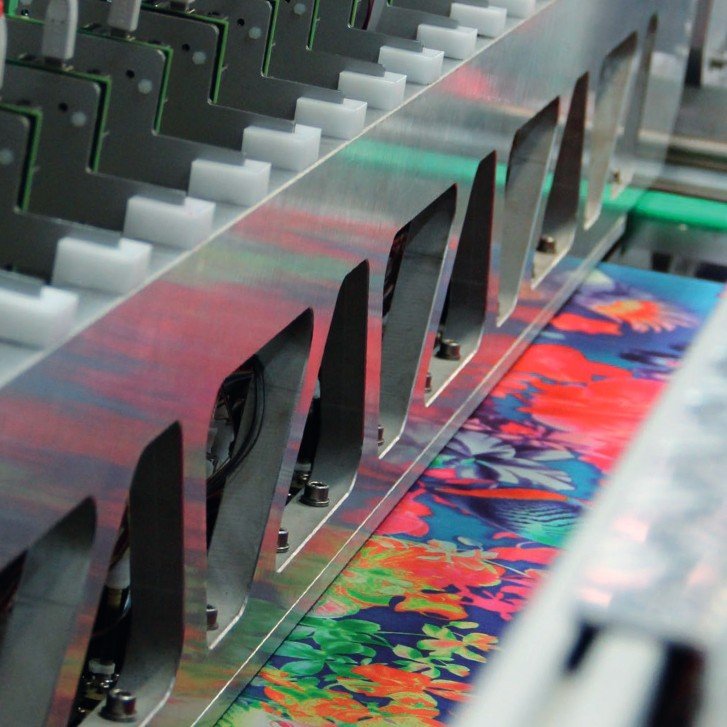

Offset, gravure printing and flexography are one of the most typical sorts of traditional printing in the product packaging area and each involves moving the image from a plate to the surface area. To do this, initially home plate requires to be created, and it is the development of these plates that take some time, and cost cash.According to PMMI, digital printing permits brands and makers to react rapidly to consumer demands while boosting the supply chain, reducing warehousing cost and waste, and delighting in faster time to market. That all sounds terrific, yet just how does this innovation do all that? The major differentiator of these modern technologies is that there are no set-up costs and no plates with electronic printing.

This results in quicker turn-around time and lowers cost when making use of electronic printing.

Rapid manufacturing suggests getting your product to market much faster. It also implies it's less complicated and faster to make adjustments in the future, when you transform a dish, add a SKU, or create seasonal product packaging. Digital printing is extremely adaptable, so it's easy to make adjustments to the package style swiftly. Everything goes back to the plates.

24hr Media for Dummies

With traditional printing techniques, short-run printing is simply not feasible. Due to the fact that a fantastic design can make or break your item, electronic printing constantly produces top notch, clear and vibrant graphics each time.

Packing ... Are you aware of the benefits of electronic printing? Check out on to comprehend when digital printing can be the most effective feasible option for your company. Do you understand why electronic printing has ended up being the preferred choice of some businesses? Both countered and digital printing have their place in the printing sector.

In this write-up, we will talk about the benefits of digital printing to aid you much better comprehend if digital printing is simply what you need. Put simply - digital printing prints product straight onto the paper. It eliminates some steps required in balanced out printing, like creating metal plates. Inkjet printers use tiny nozzles to spray droplets of ink onto the substratum.

24hr Media Things To Know Before You Get This

As digital printing constantly develops, it supplies more possibilities and higher output high quality every day. In many cases, the print high quality can be as high regarding counter printing. As years pass, digital print is becoming a lot more accessible, with boosted rate and high quality. This is simply the factor printing business are including electronic printing to their deal.

For offset printing, if any mistake goes unnoticed prior to creating home plates, there will be a high cost of producing a brand-new one. With electronic printing, this is not the instance (Point of sale stands). Although everyone always hopes there will certainly be no blunders, recognizing the expense of fixing them if they happen is constantly an excellent concept.

This suggests each and every single item will certainly look the exact same, so the opportunity you will need to dispose of any one of them as a result of variances is reduced. Given that a proofing sample is printed on the very same machine as the product itself, shade proofing is extremely precise. Any type of troubles with color will show up on the evidence, and therefore it will certainly be possible to change it prior to printing the whole run.

Indicators on 24hr Media You Should Know

Digital printing, on the other hand, requires very little arrangement. There are less pre-press procedures, so the initial setup time is substantially decreased. Therefore, turnaround is noticeably quicker. Your order can be processed as quickly as you send it. This useful site is fantastic when you are in a hurry to get your printed materials.

This suggests more demands for digital on-demand print production. Every consumer appreciates a tailored message. One of the advantages of electronic printing is that customizing your marketing materials could not be simpler. Cost-effective, smaller sized sets allow services to tailor each order. Have a back-to-school sale? Make a leaflet to target parents and another one to target the trainees.

Digital printing is the ideal option for variable information printing, like custom codes and addresses on direct mail. With digital printing, it is less bothersome to make final changes to your design. In some cases the most effective type of communication is not electronic. In these cases, depending on digital printing can guarantee these orders have a very little environmental effect.

Getting The 24hr Media To Work

There is also no demand to cleanse the plates after printing. The advantages of electronic printing consist of that there is no waste from additional or remaining ink, paper, or chemicals due to the fact that only what's needed obtains printed. - for very brief runs, digital printing is the way to go, certainly.

Gone are the days of complicated configurations and lengthy turn-around times - digital printing has actually revolutionised the print sector. The printing world has actually come a long means because the days of Gutenberg's printing machine. The brand-new typical is structured procedures and economical solutions for publishing onto virtually anything you can think about.

Report this page